Home appliance or household appliance refers to various electrical and electronic appliances used in homes and similar places, home appliance molding parts are the plastic components that make up the product.

Household appliances help people save time doing housework, creating a more comfortable and beautiful living and working environment for human beings, providing rich and colorful cultural and entertainment conditions, becoming a necessity for modern family life.

The popularity of household appliances has been nearly a hundred years old. The range of household appliances varies from different countries. There is no unified classification of household appliances in the world. Some countries have classified lighting equipment as a category of household appliances, and listed audio-visual appliances as entertainment products, and entertainment appliances also include electric electronic toys.

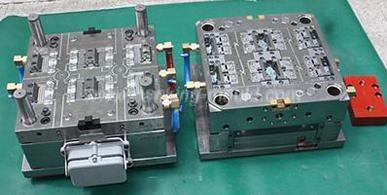

Main parts for home appliance moulds are kitchen appliances, we have coffee machine series, water Purifier, sewing machine, embroidery machine, water dispenser, air conditioner, fan, air dehumidifier, vacuum cleaner, washing machine, hairdryer, rice cooker, microwave, electric oven, dishwasher, etc..

The proportion of high-quality products for home appliances continued to increase. Driven by consumption upgrades and update demand, mid-to-high-quality home appliances have become mainstream in the market.

Although people's demand for high-quality home appliances is increasing, there are more and more home appliance brands, the competition is quite fierce. In this case, while controlling costs and providing good quality is the key to winning, and moulds are the key to determining the quality of the products.

Choose HANKING, we will guarantee the molding quality of your home appliances projects.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.