POM is polyformaldehyde, a linear polymer with no side chains, high density, and high crystallinity.

POM is polyformaldehyde, a linear polymer with no side chains, high density, and high crystallinity.

Color of POM is generally white particles.

1. The general density is 1.41-1.43g/cm3, which is a tight, rigid and elastic material with low friction resistance.

2. Thermal performance: POM has a high thermal deformation temperature, with a homopolymerization temperature of 136 ℃ and a copolymerization temperature of 110 ℃. However, due to the difference in molecular structure, the copolymer formaldehyde has a higher continuous use temperature. Generally speaking, the long-term use temperature of homoformaldehyde is around 100 ℃. Copolymer formaldehyde can be used continuously for 2000 hours at 114 ℃ or 1000 hours at 138 ℃. The temperature that can be used for a short period of time can reach 160 ℃. According to UL regulations in the United States, the long-term heat resistance temperature of polyformaldehyde is 85-105 ℃.

3. Electrical performance: It is a material with excellent electrical insulation performance, and its volume resistivity is 1 × 1014 Ω. cm, with a surface resistivity of 1 × 1016 Ω. cm, electrical strength>30MV/m, easy to modify into conductive and anti-static materials, modified volume resistivity of 1x10 Ω. cm, with good conductivity.

4. Fire resistance performance: Its oxygen index (LOI) is 15%, making it easy to burn, making it difficult to reach the flame retardant level of UL94V-0.

5. Weather resistance: The weather resistance of co formaldehyde is better than that of homoformaldehyde. For example, co formaldehyde with UV stabilizer has better weather resistance and is suitable for outdoor use. Excellent thermal aging resistance.

6. Chemical resistance: Copolymer formaldehyde has excellent chemical resistance and can effectively resist various chemicals such as organic fats and synthetic detergents.

7. Unresistant chemical substances: strong acids and oxidizing agents, concentrated nitric acid can quickly attack POM. Perfluoroacetone can form extremely dilute solutions.

8. Hydrolysis resistance: Excellent hydrolysis resistance, suitable for long-term use in 80 ℃ hot water.

1. Automotive industry: door lock springs, wiper motor system gears, combination switches, carburetor gasoline buoys, fuel tank covers, door lock side covers, radiator discharge valves, automatic car door lock mechanisms, car antenna systems, remote door reflectors, etc.

2. Electronic and electrical: switches, keyboards, buttons, audiovisual tape reels, power tools, garden organizing tool parts, electric fan parts, watch micro gears, plugs, switches, buttons, relays, shaft and wheel housings of cassette tapes, parts of cameras and other precision instruments.

3. Household appliances: various parts of televisions, washing machines, refrigerators, telephones, cassette recorders, dishwashers, etc.

4. Mechanical industry: transmission components such as gears, drive shafts, chains, valves, valve stem nuts, bearings, cams, impellers, rollers, nozzles, guide rails, bushings, pipe joints, and mechanical structural components.

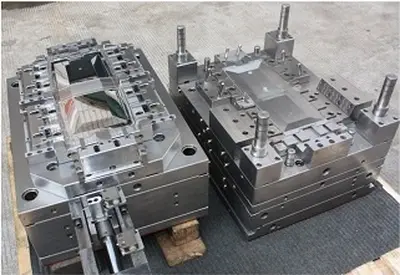

1. Steel: Due to the decomposition of corrosive gases or wear caused by glass fibers during POM injection molding, the selection of plastic mould materials needs to consider both wear resistance and corrosion resistance. Nitriding and quenching treatment are beneficial for enhancing wear resistance.

2. Runner gate: It is recommended to use circular runner. If circular runner cannot be formed, we recommend to use trapezoidal runner channel and avoid using semi-circular channels. The size of the runner channel should be as large as possible, and the distribution of the channel should be symmetrical.

3. Gate: The thickness is 60-70% of the thickness of the injection molded product. The width is 1-1.5 times the thickness of the gate.

4. Draft angle: The commonly used draft angle is 1 °, with a minimum of 1/4-1/2 °.

5. Exhaust port: A rough surface of about 1/100 can be designed on the outer circumference of the plastic injection molding parts, and a venting groove of about 1mm can be designed for POM plastic mould.

1. Drying: The moisture absorption of the POM resin itself is very low, so it does not necessarily need to be dried. However, when molding, if the water content is greater than 0.1%, drying is necessary to avoid mold scaling. However, for some filling grades, such as carbon fiber filling and conductive grades, drying must be carried out at 80-90 ℃ for 3-4 hours.

2. Recycling: Recycled materials can be used. Even if 100% of the recycled material is used 10 times, its physical properties will not change, but the color will change. In principle, it is recommended to mix 25-30% of the recycled material with 75-70% of the new material.

3. Thermal stability: After staying at a temperature of 210 ℃ for 60 minutes before molding, the tensile strength of the injection molding parts remains almost unchanged. POM has good thermal stability.

4. Injection molding machine: Use ordinary injection molding, with a clamping force greater than the projected area of the injection molded product x40-60MPa.

5. Cylinder capacity: The product weight is generally 40-80% of the cylinder capacity.

6. Nozzles and locking systems: Open nozzles can be used, but to prevent overflow, it is best to choose a locking nozzle for POM injection mold.

7. Screw: Standard screw is sufficient for a POM plastic mould, with a compression ratio of 2.8-3.0:1 and a aspect ratio of 18-22:1.

8. Barrel temperature: The melting point of the resin is about 165 ℃, and the optimal temperature for actual molding is 190-210 ℃, preferably 200-210 ℃.

9. POM mold temperature: The standard mold temperature is 60-80 ℃. Depending on the characteristics of the injection molded product, surface condition, changes in size during use, and molding cycle requirements, the plastic mould temperature needs to be adjusted. Sometimes, in order to reduce the molding cycle, the mold temperature is set at 30-40 ℃, but it is easy to leave residual strain and not achieve a good appearance.

10. Injection pressure: The flowability, shrinkage, and physical properties of the resin should be considered for setting. Generally, it is above 98MPa. The holding pressure is 49-98MPa.

11. Injection speed: between 5-50mm/s, but factors such as the shape, wall thickness, quality requirements, runner thickness, and gate size of the injection molded product should be considered for setting.

12. Back pressure: In order to stabilize the measurement and prevent material dripping from the nozzle, it is recommended to set the POM plastic mould back pressure to 0.5-1.0MPa.

13. Screw speed: Plastic mould maker usually suggest 100-150rpm.

14. Molding shrinkage rate: The molding shrinkage rate is relatively large, up to 2-3.5%.

15. Secondary processing: capable of engraving, tapping, pressing, metal inserts, cutting, and other secondary processing.

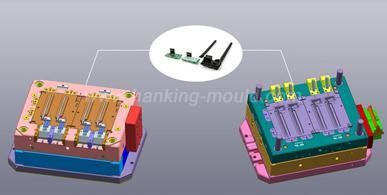

HanKing Mould is POM injection molding expert, contact us freely, send email to yoyo@hanking-mould.com for more support about your new plastic mould project.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.