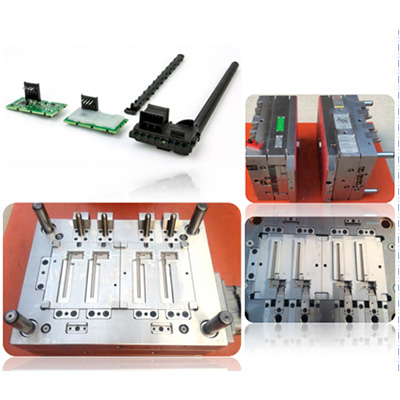

Mould Name: Car PWG final sensor Mould

Part Material: Zytel FE5382

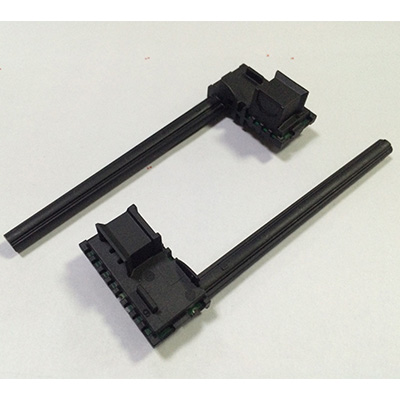

Product Size: 155.7mm

Product Description: Plastic final sensor

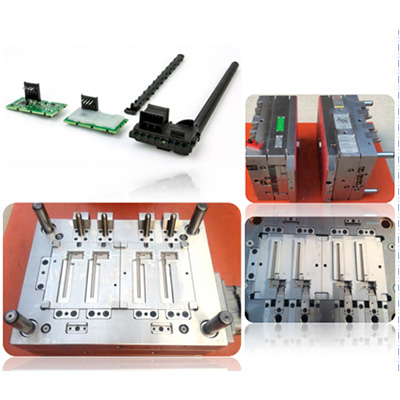

Mould Cavity: 4 cavities (one fix side and two moving sides)

Mould Size: 610*565*850MM,870*540*470MM

Suitable Injection Machine: vertical 120 ton

Mould Cavity Steel: S7

Mould Injection System: 4 DROP HUSKY HOT RUNNER SYSTEM

Mould Ejection System: Round ejector

Mould Life Cycle: 1,500,000

Lead Time: 42 working days

Mould Features: PCBA Overmolding

Mould Maker: HanKing Mould Engineering Ltd.

The challenge for this mould: Since the need for overmold PCBA, so we need to make sure the PCBA will not be damaged during the injection molding process, the protection to PCBA is very important, then first process is to overmold PCBA using TPE material. And the length of the spline is very long up to 155.7mm, and also very thin, so it may be deformed when spline top and bottom is assembled together. So how to control the deformation is also very important to this kind plastic injection mold.

HanKing Mould produces all different kind fuse and connector for an international OEM company, we have a lot of experience to short the project development time.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.