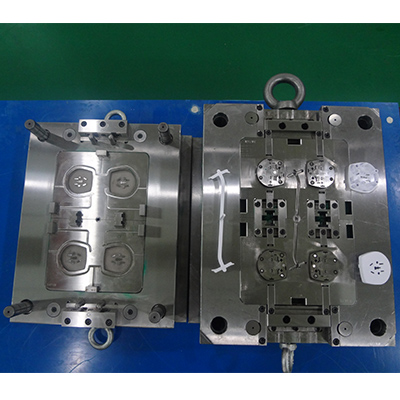

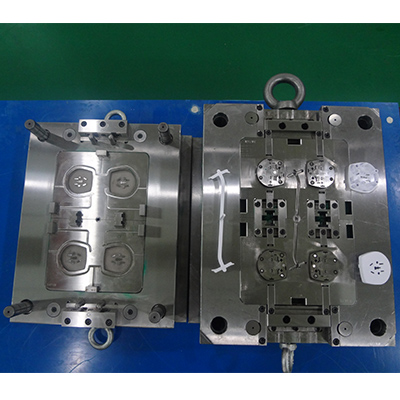

Mould Name: Adapter Charger Housing Mould

Part Material: PC

Product Size: 58.3*57.9*8.6mm

Product Description: Adapter Charger Housing UK

Mould Cavity: 4 Cavities

Mould Size: 400*450*343MM

Suitable Injection Machine: 160 ton

Mould Cavity Steel: ASSAB8407

Mould Injection System: Cold runner w/ tunnel gate

Mould Ejection System: Ejector Pin

Mould Cycle Time: 26's

Mould Life Cycle: 500,000

Lead Time: 60 days

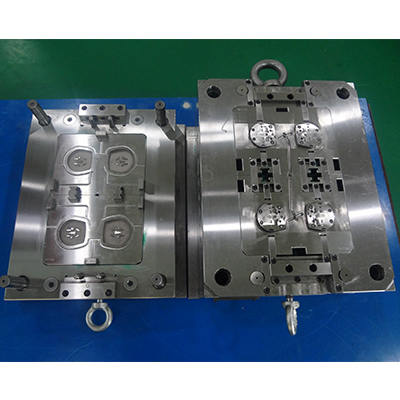

Mould Features: 8 Sliders

Adapter mold is also AC charger mold, HanKing has made a lot of such moulds. For the adapter mold or AC charger mould, the appearance is important as well as the part dimension.

First, we should choose the parting line of the part, parting line in cavity side, and parting line in the core side and it's very important to get customers' approval for the parting line.

The mold designer must choose the appropriate gate position and diameter of the gate according to the structure of the product and the requirements of the clients. For this charger mould, we normally suggest using point gate.

How to release the plastic adapter from the mould also requires careful consideration by the designer. Designers must carefully study the structure of the product, using sliders, lifters and ejection mechanisms to help the product smoothly get out of the mold cavity.

Manufacturing tips: shut-off angle along the slider moving direction as well as polishing the steel along the direction of product removal.

When some areas make the mould ejection out difficulty, find out the solution and send a proposal to the customer.

Try to make insert in the complicate area and to confirm the split line of insert pin with customers.

Reasonable use of ejector pin, ejector sleeve, ejector blade, etc. mechanisms, the distribution of the ejector pin should be even and balance.

The texture and polish are different in the cavity and core of the mould.

Most of the time, the plastic part drawing from the customer is not designed with a draft angle, we should propose to increase the draft angle within the allowable range.

It should be recessed on the bottom surface to avoid sink mark because of the wall thickness of the pillars.

The designer should check if any ribs or holes are not able to put ejector pin.

Sharp steel is must be avoided.

HanKing Mould has excellent experience in Adapter Charger Mould, we made Adapter Mould for different country standard, good water cooling to get the beautiful part surface, and automatic ejection.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.