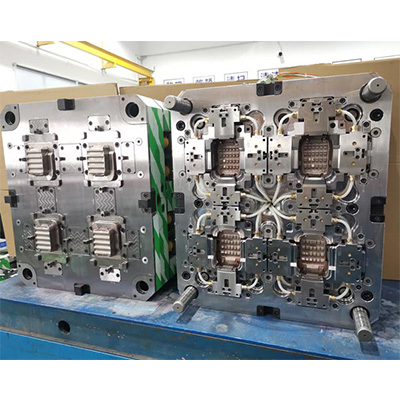

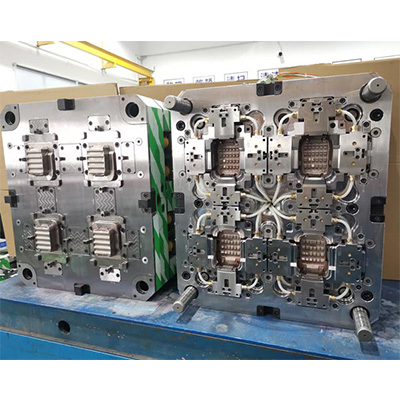

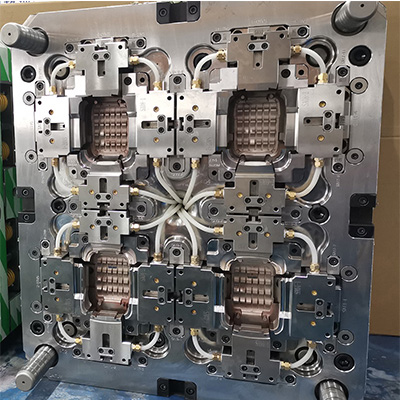

2K mold for Bosch

Product Type: Plastic parts for battery cover

Production Material: PC/ABS, TPE

No of Cavities: 4

Mould Material: Steel

Shrinkage: 0.5%

Surface: VDI3400_ref27

Type of gating: Valve gate

Lead time: 6 weeks

Tooling life: 500,000

Export to: Europe

What is the 2K mold?

Two plastic materials are produced on the same injection molding machine, and are molded in two times, and the product is only released once.

The difference between 2K mold and overmolding mold is that, 2 mold only need one mold, overmolding mold need two molds.

What is the Advantage for 2K mold?

The molding process is fast, the appearance of the processed products is more beautiful, and it can process precise two-color or even multi-color (multi-color or multi-material injection molding, need to add the corresponding barrel and screw plasticizing device) products; for products that are difficult to bond, For example, the bonding of hard plastic PA and soft plastic TPE, using 2K mold injection molding, is better than the overmolding mold.

2K injection molding products have high quality stability, easy control of product deformation, short molding cycle and high output.

What can HanKing Mould do for 2K mold?

Feasibility analysis of two-color plastic products.

Viscosity Compatibility analysis of two plastic materials

2K mold design.

HanKing Mould - Professional 2K mold making factory.

One - stop service for 2K molding production.

Hanking mould with 20 years of 2K mold experience, please contact us for a free analysis and quotation of your 2K (two colors) plastic parts. Send your 2K mold RFQ to yoyo@hanking-mould.com.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.