Plastic products tooling are also known as plastic parts moulding, plastic components molding. Plastic products tooling is a method of producing custom moulds for plastic components. Since one mold can consistently produce plastic products, production costs are reduced, making your components affordable.

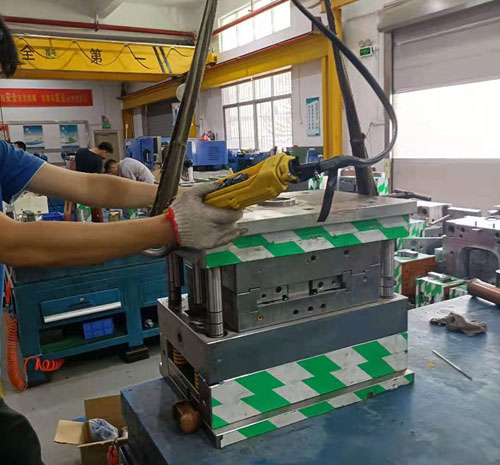

Some plastic products tooling materials are aluminum, but we HanKing Mold use steel to make tooling, steel is more high hardness and longer production life.

After the plastic is heated into a melt at a high temperature in the injection molding machine, it enters the plastic products tooling and is formed into your plastic products. During this process, there will be professional cooling equipment to help cool the mold quickly. After the mold is opened, inside of the mold there are ejector mechanism pushes out the product, and the product falls freely, and some take out the product by manually or robot, a production cycle is completed, also means the start of another production.

Although this production process seems simple, it is not easy to make a high-quality plastic products tooling. First, it is necessary to ensure that the structure of the product can be realized, which means that the product can be successfully come out from the mold.

When your product is in the design stage, HanKing mould can provide you with professional advice in terms of molds to avoid difficulties in making injection tooling after the product is designed, to saves products design rework time and cuts unnecessary costs.

Please send email to yoyo@hanking-mould.com, we will have engineers team giving you proposal for your plastic products.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.