We are plastic injection mold factory not trading company.

Auto plastic material: PA66

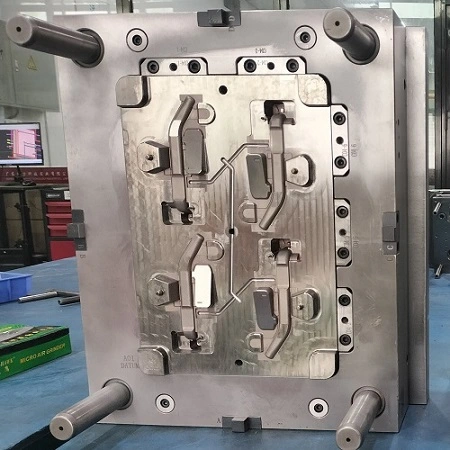

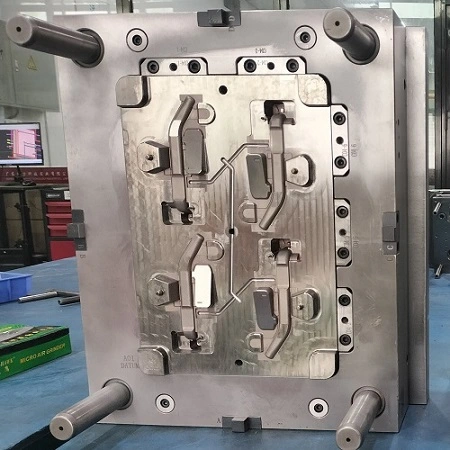

Product Description: Injection Mold for Trans Wrg Harn Bracket

Mould Cavity: 4 Cavities Automotive mold

Cavity Steel: S136

Injection System: hot runner

Ejection System: ejector pin

Cycle Time: 30's

Life Cycle: 1,000,000 shots

Lead Time: 35 working days

Tooling Maker: HanKing Mould Engineering Ltd.

Mold export to: USA

Price reference: US$20,000

The product full name is transmission wiring harness bracket, it is a component of a car connector kit made of plastic.

You can't think about automotive injection mold without thinking about HanKing Mould. This is an export automobile plastic injection mold transported to the United States, our client is an injection molding factory located in the United States, whom providing automotive parts plastic injection molding services to one of the largest automotive manufacturer in the United States.

Out of the 400 sets of plastic injection moulds we manufacture each year, one-third, or over 100 sets, are automotive parts molds.

Our injection molds are also exported to European countries such as Germany, Switzerland, Hungary, Spain, Italy, and the United Kingdom.

HanKing Mould has high-precision CNC machine tools, electric discharge machining machines, wire cutting machines, and injection molding machines. CNC lathes, CNC milling machines, high-precision grinding machines and other equipment, and equipped with precision testing equipment such as coordinate measuring machines and engineering machine tools. In order to align our company with the world, we have established a team of experienced engineers who can meet any of your needs and gain a good reputation from the international market。

With the rapid development of automotive electronic technology, the proportion of automotive electronic functions in automobiles is increasing. The increase in electronic functions has led to an increasing number of vehicle circuits, making it increasingly difficult for automotive research departments to arrange vehicle circuits. In addition, messy wiring harnesses may cause danger due to friction or collision with nearby parts during vehicle operation. Therefore, it is necessary to arrange the messy wiring harness in a beautiful and reasonable manner in a limited space.

Car wiring harnesses are the main network of car circuits, and without wiring harnesses, there would be no car circuit. Transmission wiring harness usually refers to a component that is formed by stamping contact terminals (connectors) made of copper material and crimping wires and cables, and then molding insulation or adding metal shells outside to form a connecting circuit by bundling the wiring harness.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.