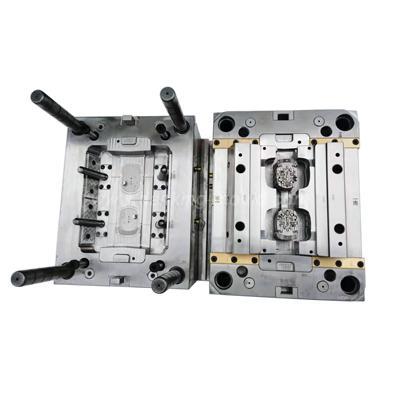

HanKing Mould can provide in-house Plastic injection molding services, offering you with the best plastic mold making service and saving effective cost. As a China plastic injection molding manufacturer, HanKing Mould Engineering Ltd. also has long-term and stable relationships with international and domestic suppliers of raw materials and accessories to offeri time flexibility.

We had experience in various thermoplastic resins including engineering resin such as ULTEM, PEEK, PPS, PC, LCP, PES, ABS, PBT, NYLON, PP, ACETAL, Glass-filled Nylon, HDPE, HIPS, SAN, LDPE, TPE, TPU, etc. HanKing Mould team commits to providing quality plastic injection molding products, on-time lead time and superior after-sale services. The skilled technology, rich experience & excellent ability to solve problems that ensures high precision plastic injection moulds and good quality plastic molding parts to our global clients. If we can't make a good job, we won't accept your order. Once we accept your order, please believe that we are confident to fulfill your expectations.

If you're searching for complicated technical parts for automotive, aerospace, medical, industrial and household products, please trust HanKing Mould is the number one choice.