Mold modeling service: It usually refers to the 3D modeling of the product, focusing on the use of software. The 3D modeling of the mold structure is more focused on the test of the 3D design software, and it also requires basic knowledge of the mold.

Mold design: the scope is relatively wide. It includes product styling, mold styling services, mold structure design, production of parts processing drawings, mold progress tracking, mold modification and adjustment, product changes, defect analysis, improvement plan formulation and so on.

The main work engaged in the design of mold modeling services includes:

1. Digital drawing-convert 3D product and mold models into 2D engineering drawings used in conventional processing;

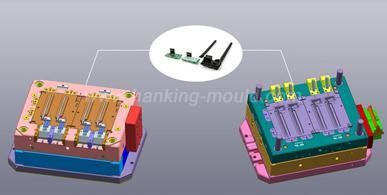

2. Digital design of the mold-according to the product model and design intent, establish a related three-dimensional solid model of the mold;

3. Digital analysis and simulation of the mold-according to the product molding process conditions, perform structural analysis, thermal analysis, fatigue analysis and mold motion analysis of mold parts;

4. Simulation of product forming process-injecting and stamping molding;

5. Customized standard parts and standard design process suitable for the company's mold design;

6. Mold production management.

The mold designer refers to the person who is engaged in the digital design of the enterprise mold, including the cavity mold and the cold die. They refer to the people who make full use of digital design tools on the basis of traditional mold design to improve the quality of mold design and shorten the mold design cycle.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.