Plastic gears are a critical component in many types of machinery, from household appliances to industrial equipment. They are cost-effective, lightweight, and can be easily molded into various shapes and sizes. In this article, we will guide you through the process of molding plastic gears.

The first step in molding plastic gears is to design the gear. You can use computer-aided design (CAD) software or any other design tool to create a 3D model of the gear. Ensure that the gear design meets the required specifications for the intended application.

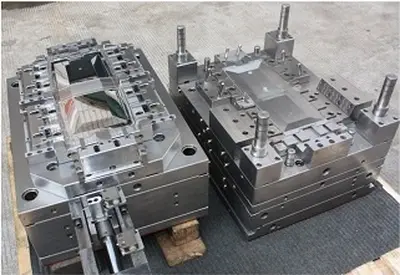

Once you have the gear design, the next step is to create the mold. The mold should match the gear's dimensions, and it should be made from a material that can withstand the injection molding process. Common materials used for molds include steel, aluminum, and copper.

After creating the mold, you need to prepare the injection molding machine. Start by preheating the machine to the required temperature. Then, load the plastic pellets or resin into the machine's hopper.

Once the machine is preheated, and the plastic pellets or resin are in the hopper, it's time to inject the plastic into the mold. This process involves forcing the molten plastic into the mold under high pressure. The plastic will take the shape of the mold and form the gear.

After the plastic has been injected into the mold, the next step is to cool the mold. This process is essential to solidify the plastic and prevent it from warping or deforming. To cool the mold, you need to run cooling water through the mold's channels.

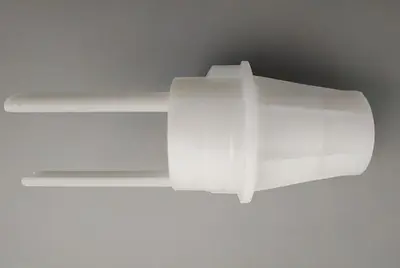

Once the plastic has cooled and solidified, you can use a hook to extract the gear from the mold. Ensure that the hook is strong enough to withstand the weight of the gear and does not damage the gear's teeth during extraction.

Molding plastic gears with a hook involves high temperatures, pressure, and molten plastic. It is important to take safety precautions to prevent injury. Always wear safety equipment, such as gloves, goggles, and masks. Also, ensure that the injection molding machine is properly maintained and functioning correctly.

Molding plastic gears is a relatively straightforward process that requires careful attention to detail. By following the steps outlined in this article, you can create high-quality plastic gears that meet the requirements of your specific application. With the right tools, materials, and safety precautions, you can produce plastic gears that are cost-effective, durable, and reliable.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.