Plastic molded parts are widely used in various industries due to their durability, versatility and cost-effectiveness. However, a common problem that manufacturers often face is the presence of air marks on the finished product. These unsightly blemishes detract from the aesthetics and functionality of plastic moldings. In this article, we'll take a deep dive into the causes of air trails and explore some strategies for preventing them from happening.

1. One of the main causes of air marks has to do with problems with the plastic material itself.

Moisture, impurities or inconsistent molecular weight in the plastic material can lead to bubble formation or gas accumulation during injection molding. When these air bubbles become trapped within the plastic, visible air marks result. To alleviate this problem, optimizing the choice of plastic materials is crucial. Plastic injection molding manufacturers should choose plastic raw materials with stable quality, low water content and few impurities. By maintaining the quality of raw materials, the generation of air bubbles and air marks can be significantly reduced.

2. Another cause of air marks is improper injection molding process parameters.

If the process parameters such as injection molding temperature, pressure, and cooling time are set unreasonably, it will hinder the flow of plastic materials and prevent the smooth discharge of gas. As a result, air marks may form on the plastic molded articles. In order to solve this problem, the injection molding process parameters must be adjusted according to the characteristics of the plastic material and product requirements. With these parameters set correctly, the plastic material will flow smoothly, allowing gas to escape without leaving gas marks.

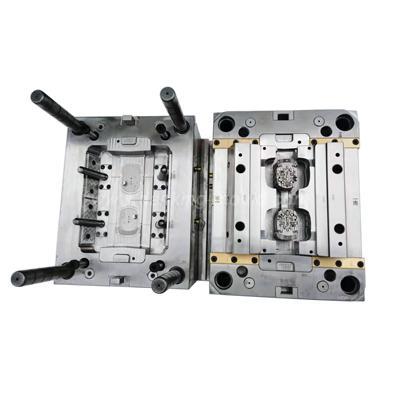

3. Injection mold design issues can also lead to the formation of air marks.

Insufficient exhaust channels in the mold will hinder the smooth discharge of gas during the injection molding process. As a result, air bubbles build up and create air marks on the plastic molded part. To solve this problem, manufacturers should prioritize improving mold design. By optimizing the injection tooling design and increasing the venting channel, the plastic material can effectively release gas and reduce the generation of air bubbles and air marks.

The most preferred method, if possible, is to add a venting pin inside the mold. During the injection process, the air in the cavity is easily expelled from the mold through the venting pin, thereby avoiding the generation of air marks on the small boss heel.

4. Unskilled operators can also be a factor in the formation of air marks.

Air marks can form on plastic molded parts if the operator is not familiar with the operation of the injection molding machine or lacks the necessary skills to precisely control the process parameters. To overcome this challenge, it is crucial to improve operator skills through comprehensive training. By providing operators with the necessary knowledge and skills, they can effectively use the injection molding machine, adjust process parameters, and solve any problems that arise in a timely manner. This will ultimately minimize the appearance of air marks.

5. Other noteworthy precautions.

A. Regular maintenance of equipment: Regularly inspect and maintain the injection molding machine to ensure its normal operation and reduce the generation of air marks caused by equipment problems.

B. Strengthen quality inspection: Establish a sound quality inspection system, conduct comprehensive testing of products, timely detect and handle products with air marks, and ensure product quality.

C. Optimize production process: Optimize production process, reduce process links, shorten injection molding cycle, and reduce the opportunity for air marks.

In conclusion, air marks on plastic molded parts may be caused by various factors, such as plastic material problems, improper injection molding process parameters, mold design problems, and unskilled operators. However, plastic molding manufacturers can prevent and reduce the formation of air marks by implementing countermeasures such as optimizing the selection of plastic materials, adjusting injection molding process parameters, improving mold design, and improving the technical level of operators. By taking these proactive steps, injection moulding manufacturers can ensure the production of high-quality plastic molded parts free of any unsightly blemishes.

The generation of air marks in plastic injection parts is a complex problem that requires comprehensive analysis and resolution from multiple aspects such as materials, processes, molds, and operators. By optimizing the selection of materials, adjusting process parameters, improving mold design, and improving the technical level of operators, measures can effectively reduce the occurrence of air marks in custom molded plastic parts and improve product quality. At the same time, strengthening equipment maintenance, quality inspection, and optimizing production processes are also important measures to reduce the generation of air marks. Through continuous improvement and optimization, the overall quality of injection plastic parts can be improved to meet customer needs.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China