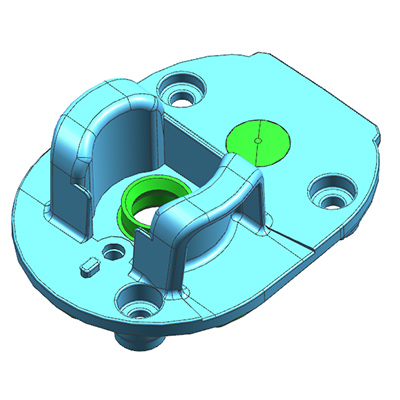

The hard plastic part is ASA

The soft plastic part is TPE

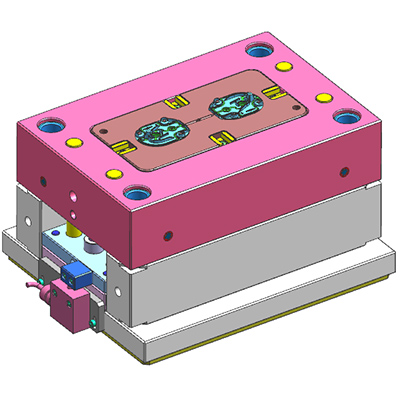

2 cavities

Hard part shrinkage: 0.55%

Sof part shrinkage: 0

Part dimension: 54.11*40.9*26.14

Gate: Sub-gate

Injection molding machine; 40-1- A 270

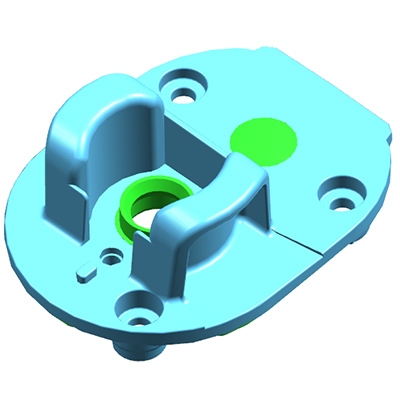

Over-molding is actually a kind of 2nd shot molding, the product consists of the main part (hard plastic part) and the outer (soft) part. When the mold is manufactured, the hard plastic parts are first manufactured. The main hard part of mold is designed in accordance with the normal design procedure. (Soft rubber) mold design should be based on the hard parts as a reference, while the core is essentially the same as the hard plastic parts, the cavity is different as there is the over-molding shape. First, produce a hard plastic part, then put the hard part into the soft part mould to over-molding the full part.

In mould design, pay attention to shrinkage calculation for the two different plastic parts. There are usually two separate sets of moulds. For over mold, the first shot part must be fit precisely into the mold for the secondary molding. Some surfaces of the first part need at zero clearance with mold surface for sealing during the secondary injection process. The other surfaces need keeping clearance for preventing pressed marks.

It should be noted that the TPU material is inherently easy to stick to the mold. If the product surface can be sand effective as much as possible, it is easy to de-mold. The TPU has a slower fluidity and a longer cooling cycle time, we should pay attention to the molding process.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.