In recent years, with the rapid development of the plastics industry and the continuous improvement of strength and precision of general and engineering plastics, the application range of plastic products is also expanding. For example, in the fields of household appliances, instruments, construction equipment, automobile industry, daily hardware, etc., the proportion of plastic products is rapidly increasing. A properly designed plastic part can often replace multiple traditional metal parts. The plasticization trend of industrial products and daily-use products continues to rise.

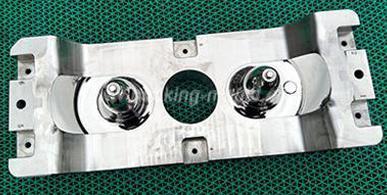

Plastic mold product refers to a combined plastic mold used for compression molding, extrusion molding, injection, blow molding and low foam molding. It mainly includes a concave mold with a variable cavity and a convex mold with a variable core. The concave mold is composed of a concave mold combined substrate, a concave mold assembly and a concave mold combined card board. The convex mold is composed of a convex mold combination substrate, a convex mold assembly, a convex mold combination card board, a cavity cut-off assembly, and a side cut-off combination board. According to the coordinated changes of the mold convex and concave molds and the auxiliary molding system, a series of plastic parts of different shapes and sizes can be processed.

In our daily production and life, the various tools and products used range from the base of the machine tool, the shell of the fuselage, to a small screw, button, and shell of various household appliances. They all have a close relationship with the mold. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold determine the quality of these products. Because of the different materials, appearance, specifications and uses of various products, the molds are divided into non-plastic plate molds such as casting molds, forging molds, die casting molds, stamping molds, and plastic plate molds.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.