Discover the hidden gems: Unearthing Italy's hottest spots for injection molding factories that are driving the future of manufacturing.

· Understanding Injection Molding Factories in Italy

· The Italian Automotive Industry and its Influence

· Distribution of Injection Molding Factories across Italy

· Statistical Analysis: Number and Distribution of Injection Molding Factories

· Challenges and Opportunities

· Reducing Injection Mold Purchasing Costs

As the automotive industry continues to evolve, injection molding plants have become key players in the manufacturing process. Italy, known for its automotive prowess, is at the forefront of this development. We will take a closer look at the distribution of injection molding plants in Italy, with a particular focus on their relationship to the Italian automotive industry.

Injection molding is a widely used manufacturing technique that involves making parts and products by injecting molten material into a mold. Its applications extend beyond the automotive industry and is valuable in various industries including consumer products, electronics and healthcare.

Italy has a rich automotive industry heritage, including well-known brands such as Ferrari, Lamborghini and Fiat. The Italian automotive industry had a profound impact on the establishment and development of injection molding plants in the country. Italian automobile design is a world leader and has a number of world-recognized automobile design masters. The Turin Automotive Industrial Park is already one of the most important centers in the world's automotive industry. There are countless local sheet metal stamping craftsmen with excellent technical traditions as well as large and small workshops that have been engaged in automobile design for a long time, and can provide world-class design, development, prototype production and other services.

The relationship between injection molding plants and the Italian automotive industry is symbiotic. These factories play a key role in the automotive supply chain by manufacturing critical components. From interior trim to exterior body panels, injection molding plants meet the needs of automakers.

In addition, collaborations and partnerships between injection molding houses and automobile manufacturers further strengthen their ties. These alliances ensure streamlined production processes, timely delivery of components and promote technological innovation.

When looking at the distribution of injection molding plants in Italy, it is clear that certain regions are the centers of the industry. The concentration of factories varies across the country due to several factors.

The presence of automobile manufacturers plays an important role in determining the distribution of injection molding plants. Regions with high automotive production densities, such as Emilia-Romagna and Lombardy, also have a significant number of injection molding companies. Proximity to transport and logistics hubs further enhances the attractiveness of these areas for such plants.

Reliable statistics regarding the exact number of injection molding factories in Italy can be challenging to obtain. However, estimates suggest that there are hundreds of injection molding companies spread across the country.

Regional analysis provides valuable insights into the distribution of these factories. Some regions, like Veneto and Piedmont, showcase a higher density of injection molding facilities. On the other hand, regions with a lower concentration, such as Calabria and Sardinia, still make notable contributions to the industry.

The distribution of injection molding factories plays a vital role in supporting the Italian automotive industry. By having factories strategically located in close proximity to automotive manufacturers, it facilitates a more efficient supply chain.

Despite the growth and significance of injection molding factories in Italy, there are certain challenges they face. Economic fluctuations, competition from other countries, and technological advancements are common hurdles. However, these challenges also present opportunities for innovation and growth.

The increasing demand for sustainable and environmentally friendly solutions in the automotive industry offers a particularly promising avenue for injection molding plants. By embracing new materials and technologies, these factories can adapt to the evolving needs of the industry and be the first to introduce breakthrough solutions.

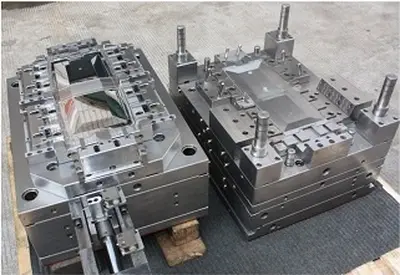

For Italian injection molding factories, reducing plastic mold procurement costs is crucial. China has mature technology and experience in plastic mold manufacturing, and its prices are relatively low, so it has certain competitiveness in the Italian injection mold market. Italy has become one of the main export destinations for China's plastic injection molds. Relying on China's strong domestic sales market, China's injection mold manufacturers have the opportunity to manufacture plastic parts for various products and have accumulated a large amount of complex precision injection mold experience. HanKing Mould Engineering Ltd. is a factory specializing in manufacturing medium-sized precision plastic injection molds, they have particular advantages in the complex molds such as high tolerance plastic parts, complex structure parts, thin wall plastic products, multi-cavity molds and two-color molds.

HanKing mould can complete very quickly from plastic product analysis, mold-flow analysis, mold design, injection tooling making, mold trial, and delivery to customer.

Going forward, the layout of Italian injection molding plants may change. The desire for efficiency and proximity to automakers will continue to influence the establishment of these plants. Growth may occur in areas with untapped potential, while further consolidation may occur in existing factory hotspots.

In addition, advances in automation, hybrid manufacturing technology and materials science will shape the future landscape of injection molding plants. The industry's ability to adapt and embrace these changes will determine its long-term success.

Italian injection molding plants play a vital role in supporting the automotive industry. Their distribution is concentrated in major automotive manufacturing regions and forms an integral part of the supply chain. Collaboration, innovation and a strong commitment to sustainability will be key to driving future growth at Italian injection molding plants, ensuring the country maintains a strong position in the automotive industry.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.