Different injection moulding moulds manufacturers take different time to manufacture a pair of injection molding mold with the same quality. Some people think that the longer the cycle, the finer the workmanship and the better the quality. In fact, this is wrong. Since they are not professional, they need more time to manufacture. What's more, since they are not professional, they need more time to repair. However, it is not that the shorter the time the better, because this complete mold manufacturing process takes time.

The normal time for a professional injection moulding moulds manufacturer to make a pair of injection molds is 50-65 days, depending on the difficulty of the mold. The minimum time for conventional molds is generally 30 days, and the longest time is generally not more than 75 days. Only professional manufacturers rely on years of production level to make high-quality injection molds.

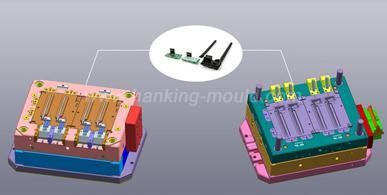

HanKing Mould Enginering Ltd. is a very professional injection moulding moulds manufacturer. We continue to innovate and optimize the mold structure, and take the responsibility of providing high-quality injection molds. For injection molds, many manufacturers can now do it. However, being able to do it does not mean that you can do it well. No matter what it is, only the most professional is the most trusted by customers. As a professional mold manufacturer, we have continuously summarized and explored in many years of mold production experience, and now has a complete set of injection mold design concepts and manufacturing processes. Every detail in the design is carefully analyzed and certified. In terms of workmanship, it is also placed in the hands of a manufacturing master who has been manufacturing injection molds for many years.

HanKing Mould Enginering Ltd. has always insisted on doing the most professional things and providing customers with the most worry-free service. We believe that our expertise can solve your problems!

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.