Appliance injection molding: advantages and application analysis

In the modern home appliance manufacturing industry, injection molding production technology has become an indispensable and important process. China plastic injection mold manufacturer and injection molding factories play a key role in the production process of household appliance plastic parts.

1. Application of Injection Molding Production in the Home Appliance Industry

A. Home appliance equipment plays a crucial role in modern life. Among them, injection molding production technology is widely used in household appliances such as washing machines, refrigerators, microwaves, and air conditioners. Injection molding production makes the manufacturing of parts for these household appliances more efficient and precise, ensuring product quality and performance.

B. Home appliance parts are usually made of plastic, such as control panels, shells, switch buttons, etc. Through injection molding production, these parts can be produced at a faster speed and maintain high consistency. Injection molding technology reduces the manufacturing cost of household appliance plastic parts, while also meeting complex design and shape requirements, bringing more innovation to household appliance plastic products.

2. Advantages of Injection Molding Production of Plastic Parts for Home Appliances

A. Efficient injection molding production technology allows for large-scale production of plastic parts for household appliances in a short period of time. After the completion of mold manufacturing, injection molding factories can quickly produce parts through automated production lines, improve production efficiency, and meet the rapid delivery needs of the home appliance industry.

B. Accurate dimensions and tolerances are usually required for household appliance parts to ensure the assembly and performance of the product. Injection mold construction manufacturing technology can accurately control the size of parts, ensure their perfect matching with other components, thus improving the overall quality and performance of household appliances.

C. The design of household appliances with complex shapes and degrees of freedom often has complex curves and special shape requirements. Through injection molding production, complex shapes can be easily manufactured, providing more design freedom and creating more attractive and differentiated home appliance products.

3、 Injection molding production process of plastic parts for household appliances

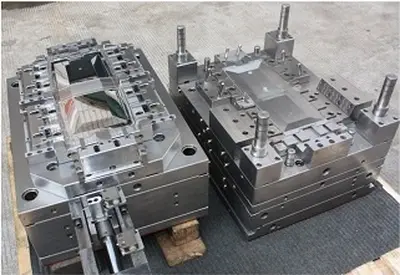

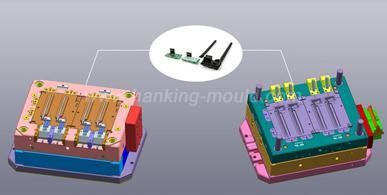

A. The injection molding production process of designing and manufacturing plastic parts for household appliances begins at the design stage. The engineer will carry out 3D design according to the function and shape requirements of home appliance parts, and make Injection mold construction. The quality and accuracy of the mold are crucial to the quality of the final product.

B. Plastic particle processing before injection molding production, plastic particles need to be processed to ensure material uniformity and fluidity. By heating and compressing, plastic particles are transformed into injection molten plastic.

C. Injection molding molten plastic is injected into a pre made mold, and after high-pressure injection and cooling, the plastic solidifies and forms in the mold. Subsequently, the mold was opened and the plastic parts of the household appliances were demolded out of the mold.

D. After post-processing and quality inspection, the plastic parts of household appliances after demolding need to undergo post-processing, such as trimming, flash removal, etc. At the same time, strict quality inspection is also required to ensure that the parts meet customer requirements and international standards.

4、 Summary

Injection molding production is widely used and crucial in the home appliance industry. With the technical support of Injection mold construction manufacturing and injection molding factories, the production of household appliances and parts has become efficient, accurate and economical. In the production process of plastic parts for home appliances, the advantages of efficient production, precise dimensions, and design freedom enable home appliance manufacturers to provide more competitive products. The continuous innovation and development of injection molding production will inevitably drive the home appliance industry to constantly reach new heights.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.