Italian injection molding factories offer several advantages that make them highly sought after in the industry. Firstly, Italy has a long-standing tradition of craftsmanship and precision engineering, which translates into the production of high-quality injection molded products. Italian manufacturers are known for their attention to detail and commitment to delivering products that meet the highest standards.

Additionally, Italian injection molding factories often invest in state-of-the-art technology and machinery. This allows them to stay at the forefront of innovation and produce complex and intricate designs with ease. The use of advanced machinery also enables them to optimize production processes, resulting in shorter lead times and increased efficiency.

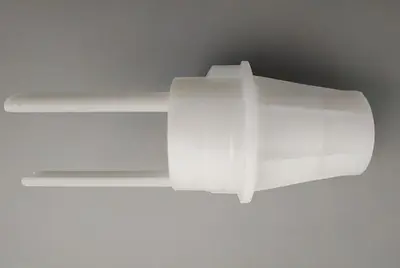

Another advantage of Italian injection molding factories is their ability to offer a wide range of materials and finishes. Whether it's plastic, rubber, or metal, Italian manufacturers have the expertise to work with various materials and create products that meet specific requirements. They also excel in providing different surface finishes, such as matte, glossy, or textured, giving customers the flexibility to choose the desired look and feel for their products.

Italian injection molding manufacturers face several challenges in today's competitive market. One of the main challenges is the increasing demand for high-quality products at lower costs. This puts pressure on manufacturers to optimize their production processes and find innovative ways to reduce costs without compromising on quality.

Italy's injection molding manufacturers are constantly seeking ways to enhance their competitiveness in the global market. One promising avenue for achieving this is by sourcing plastic injection molds from China. In this article, we will explore the numerous advantages that Chinese mold technicians bring to the table, the benefits of China's mold supply chain concentration compared to other mid-range precision mold manufacturing countries, and the time advantages offered by Chinese mold manufacturing factories over their European counterparts. By delving into these aspects, we aim to shed light on why Italy's injection molding manufacturers should seriously consider China as their go-to destination for plastic injection molds.

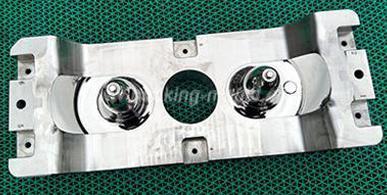

One of the primary reasons why Italy's injection molding manufacturers should source plastic injection molds from China is the cost advantage offered by Chinese mold technicians. China has a vast pool of highly skilled and experienced mold technicians who can deliver top-notch molds at a fraction of the cost compared to their European counterparts. This cost advantage stems from several factors, including lower labor costs, economies of scale, and a well-established infrastructure for mold manufacturing.

China's mold supply chain concentration is another compelling reason for Italy's injection molding manufacturers to turn to China for their plastic injection molds. Unlike other mid-range precision mold manufacturing countries, China boasts a highly concentrated and well-developed mold supply chain. This concentration allows for seamless collaboration between mold manufacturers, material suppliers, and other relevant stakeholders, resulting in streamlined processes, reduced lead times, and enhanced overall efficiency. Italy's injection molding manufacturers can benefit from this concentration by accessing a wide range of mold options, quick turnaround times, and competitive pricing.

Time is of the essence in the injection molding industry, and China's mold manufacturing factories offer significant advantages in this regard. Compared to European mold factories, Chinese counterparts exhibit faster manufacturing times, enabling Italy's injection molding manufacturers to meet tight production schedules and respond swiftly to market demands. This advantage is primarily attributed to China's well-established manufacturing infrastructure, efficient production processes, and the ability to scale up production rapidly. By sourcing plastic injection molds from China, Italy's manufacturers can gain a competitive edge by reducing lead times and ensuring timely delivery of high-quality products.

In conclusion, Italy's injection molding manufacturers can reap significant benefits by sourcing plastic injection molds from China. The cost advantages offered by Chinese mold technicians, the concentration of China's mold supply chain, and the time advantages provided by Chinese mold manufacturing factories make China an attractive destination for Italy's manufacturers. By embracing this strategic move, Italy's injection molding industry can unlock cost efficiency, enhance manufacturing excellence, and stay ahead in the global market.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China