TPE overmolding with ABS refers to the use of secondary injection molding to spray and stick TPE soft rubber encapsulation onto the surface of ABS products. Usually, ABS is injected first, followed by TPE injection. Secondary injection molding not only fills the surface of the equipment with softness, but also increases product functionality and added value.

First off, let's talk about why TPE is such a fantastic sticky material for overmolding with ABS. TPE, or thermoplastic elastomer, boasts a unique set of characteristics that make it ideal for this application.

One of the standout features of TPE is its flexibility and elasticity. This allows TPE to easily conform to complex shapes and provides a soft touch feel that enhances the overall user experience. Additionally, TPE has excellent bonding properties with ABS, ensuring a strong and durable connection between the two materials.

Moreover, TPE is resistant to chemicals and UV rays, making it a reliable choice for outdoor or high-traffic applications. Whether you're creating automotive parts, electronics, or medical devices, TPE's versatility shines through in every use case.

The application of ABS and TPE dual material overmolding not only provides the product with basic usage properties, but also increases its grip softness, comfort, and anti slip properties, invisibly enhancing the added value of the product. Widely used in industries or products such as automotive parts, medical products, daily necessities, hardware tools, sports and fitness equipment for users.

If you're new to the concept of overmolding, don't worry - we've got you covered. Overmolding is a manufacturing process where a second material (in this case, TPE) is molded over a base material (ABS) to create a single integrated product.

The process typically involves several steps, including preparing the base material, molding the TPE over it, and allowing the materials to bond together. The result is a product that combines the strength and rigidity of ABS with the flexibility and softness of TPE, offering the best of both worlds in one seamless package.

By using TPE as a sticky material in the overmolding process with ABS, manufacturers can achieve a perfect balance of durability, aesthetics, and functionality in their products. It's a win-win situation for both producers and consumers alike.

The versatility of overmolded products knows no bounds. From the automotive industry to electronics, medical devices, and consumer goods, the applications are endless. Let's take a closer look at some real-world examples of overmolded products in action.

In the automotive industry, overmolded parts offer increased durability and improved aesthetics. Think about those sleek and comfortable steering wheel grips or impact-resistant dashboard components - all made possible by the combination of ABS and TPE.

When it comes to electronics, overmolded products provide enhanced grip and protection for devices like mobile phones, laptops, and wearables. The soft touch feel of TPE adds a premium touch to these products while ensuring they can withstand daily wear and tear.

In the medical sector, overmolded devices offer enhanced comfort and functionality for patients and healthcare professionals alike. From ergonomic handles on surgical tools to cushioned grips on medical devices, ABS and TPE work together seamlessly to deliver superior performance.

Let's delve into some case studies to see the power of TPE and ABS in action. These real-world examples showcase the impact of overmolding on various industries and highlight the benefits of using these materials in tandem.

For example, in the automotive sector, overmolded parts like door handles and gearshift knobs demonstrate the durability and aesthetic appeal of combining ABS and TPE. These components not only look great but also offer a comfortable and secure grip for drivers.

In the electronics industry, overmolded products like protective cases and cable connectors benefit from the superior bonding and flexibility of TPE. These products not only provide added protection but also enhance the user experience with their ergonomic design.

In the medical field, overmolded devices such as prosthetic limbs and medical instruments showcase the versatility and comfort of ABS and TPE. These products are designed to be durable, flexible, and user-friendly, catering to the unique needs of patients and healthcare professionals.

As we wrap up our exploration of TPE as the ultimate sticky material for overmolding with ABS, it's clear that these materials are a match made in manufacturing heaven. The flexibility, durability, and aesthetic appeal of overmolded products are unrivaled, thanks to the unique properties of TPE and ABS.

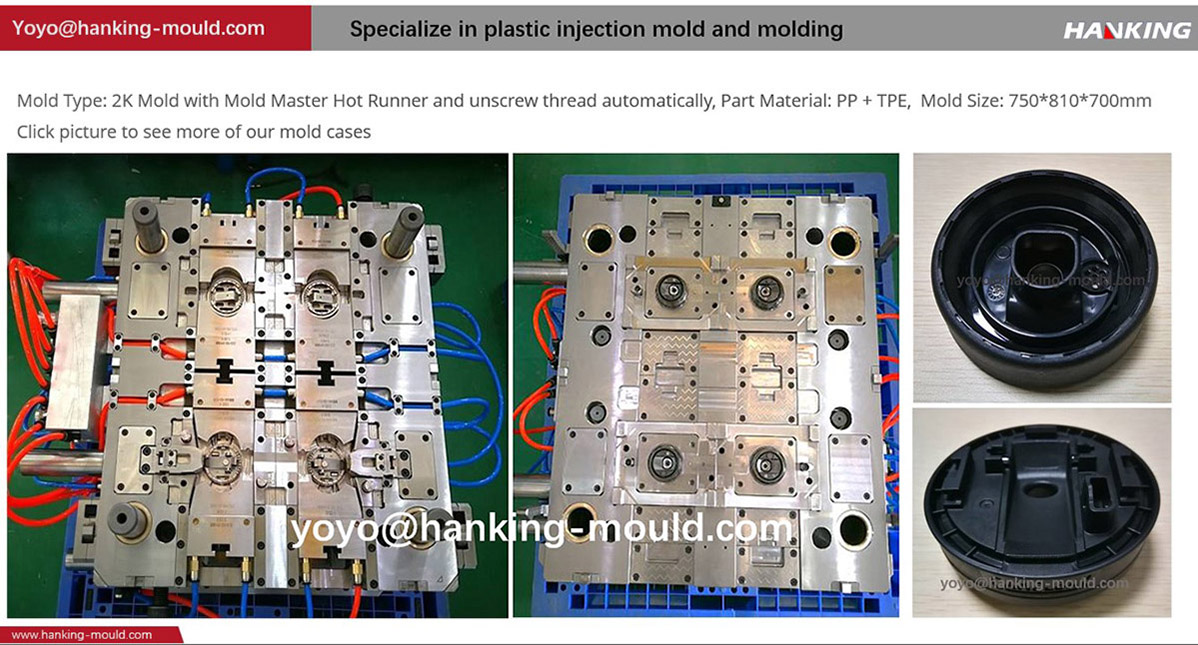

So, whether you're designing automotive parts, electronics, medical devices, or consumer goods, consider incorporating TPE into your next overmolding project for superior results. The perfect pair of TPE and ABS is waiting to elevate your products to new heights - so why wait? Contact us to start your overmolding production projects, send inquiry to yoyo@hanking-mould.com.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China