Have you ever wondered how all those cool plastic toys, gadgets, and even car parts are made? Well, get ready to dive into the fascinating world of plastic creation with a super cool method called injection molding! Let's explore how plastic parts come to life through this amazing technology.

What is Injection Molding?

Injection molding is like magic for creating plastic things. Imagine a big machine that melts plastic, then squishes it into a special mold to make all sorts of shapes. It's like pouring pancake batter into a mold to get pancakes in different shapes!

Why Use Plastic Injection Technology?

Injection molding is awesome because it can make a lot of plastic parts really quickly and with great precision. This means we can have all the toys, tools, and tech we love in no time!

The Journey of a Plastic Part

Before a plastic part is made, smart people think about and draw what they want it to look like. This step is like planning a cool art project!

Choosing the Right Plastic

Not all plastics are the same. Just like picking the right color for a drawing, people need to choose the perfect type of plastic for the job. Some plastics are tough, while others are bendy like a rubber band!

The Molding Machine Magic

Imagine a big machine that can melt plastic and shape it into all sorts of cool things. That's what a molding machine does! It uses heat and pressure to turn gooey plastic into neat shapes, like making a snowman out of snow.

Getting into Shapes: Moulds and More

When it comes to creating plastic parts, one essential element in the process is the mould. Let's take a closer look at how moulds play a crucial role in shaping the plastic into all sorts of cool things!

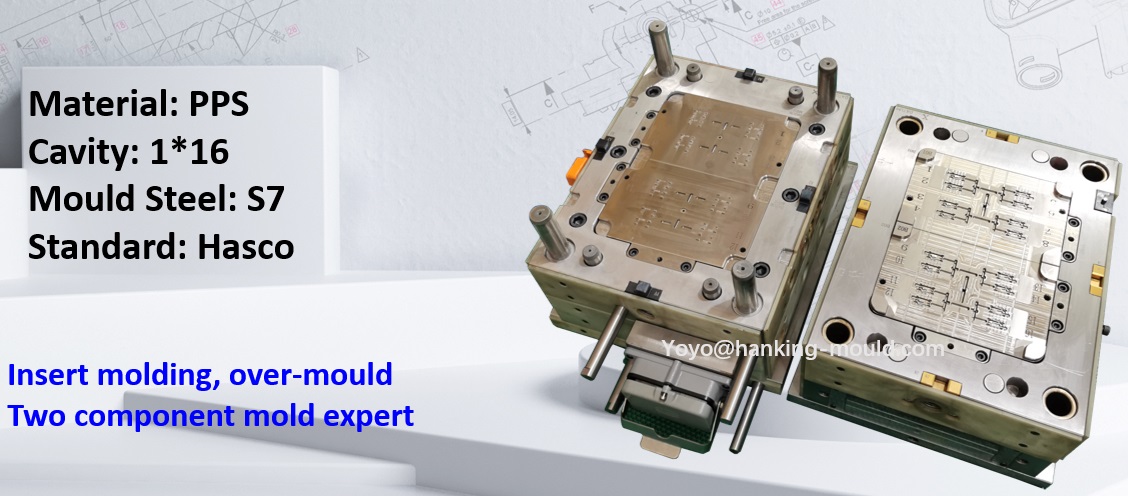

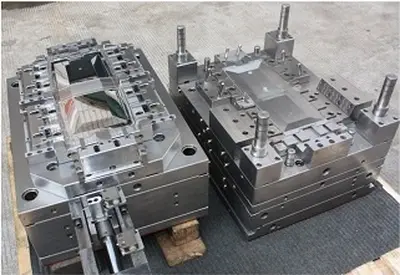

Creating the Mould

Imagine a mould as a special container that has the exact shape of the plastic part you want to make. It's like a cookie cutter, but for plastic! Skilled designers and engineers carefully craft these moulds to be precise and accurate, ensuring that every plastic piece comes out just right.

Moulding Techniques

Now that we have our mould ready, it's time to fill it with molten plastic. There are different techniques used to do this, each offering unique advantages. Some methods involve injecting the plastic into the mould at high speeds, while others use compression to shape the material. These techniques allow manufacturers to create a wide variety of shapes and sizes, from intricate details to large, sturdy parts.

Troubleshooting in Plastic Making

Learning about some common problems when making plastic parts and how smart people fix them.

Oops! Air Bubbles

Air bubbles can be a problem when making plastic parts. Sometimes, air sneaks into the plastic when it's being molded, creating little pockets of air that can make the part weak or not look right. To get rid of these pesky bubbles, experts use special techniques like adjusting the temperature of the mold or changing how the plastic is injected into the mold. This helps make sure that the plastic comes out bubble-free and strong!

Cracks and Weak Spots

Sometimes, plastic parts can end up with cracks or weak spots. This can happen if the plastic isn't heated or cooled properly during the molding process, or if the mold isn't the right shape. To fix this, engineers work on improving the design of the part or adjusting the molding machine settings to make sure the plastic flows smoothly and evenly. By making these adjustments, they can prevent cracks and weak spots, creating sturdy and reliable plastic parts.

Plastic Parts Everywhere!

Have you ever stopped to think about how many plastic parts are around you every day? From the toys you play with to the tools your parents use, plastic parts made through injection molding are everywhere!

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.