Table of Contents

· ABS injection molding material properties

· Application fields of ABS injection molding pellets

· Steel selection for ABS injection mold

· ABS injection molding process conditions

ABS, commonly known as acrylonitrile butadiene styrene, is a copolymer of three monomers: acrylonitrile-butadiene-styrene. Due to the different proportions of the three monomers, different properties and melting temperatures can be achieved. If ABS with flow properties is blended with other plastics or additives, it can be expanded to ABS with different uses and properties, such as impact-resistant grade and heat-resistant grade., flame retardant grade, transparent grade, enhanced grade, electroplating grade, etc.

ABS appearance is an opaque ivory-colored particle with good thermal stability. ABS injection molding shrinkage is 0.4%-0.9%, and HanKing Mould generally use ABS mold shrinkage 0.5% in practical applications. ABS plastic must be dried before processing. About ABS injection molding temperature, the general product drying conditions are temperature 80 to 85°C and time 2 to 4 hours. Products with special requirements (electroplating, etc.) require a temperature of 70 to 80°C and a time of 18 to 18 hours. For heat-resistant ABS containing PC components, the drying temperature should be appropriately increased to 100°C, and the specific drying time can be determined by extruding it into the air.

ABS injection molding pellets has excellent mechanical properties, its impact strength is very good, and it can be used at extremely low temperatures. ABS has excellent wear resistance, excellent dimensional stability and oil resistance, and can be used in bearings under moderate loads and high speeds. ABS is more resistant to creep than PSF and PC, and lower than PA and POM. The flexural strength and compressive strength of ABS are insufficient among plastics. The mechanical properties of ABS are highly sensitive to temperature.

The heat distortion temperature of ABS is 93-118℃. After annealing, the product will rise approximately 10°C. ABS shows some toughness even at -40℃ and can be used in the temperature range of -40 to 100℃.

ABS injection molding pellets has high electrical insulation properties, is virtually unaffected by temperature, humidity and frequency, and can be used in most environments.

ABS injection molding pellets is not affected by water, inorganic salts, alkali and various acids, but it is easily soluble in ketones, aldehydes and chlorinated hydrocarbons, and can cause stress cracks when invaded by glacial acetic acid, vegetable oil, etc. ABS has low weather resistance and tends to deteriorate due to the effects of ultraviolet rays. When used outdoors for half a year, the impact strength will be halved.

Like PS, ABS injection molding pellets is a thermoplastic resin with excellent processing properties and can be processed by conventional processing methods. ABS melt flow (such as PVC and HIPS) is better than PVC and PC, but inferior to PE, PA and PS. ABS flow characteristics are Newtonian fluids, which have melt viscosity, processing temperature and shear rate, but are easily affected by shear rate.

Due to its high mechanical strength and good comprehensive properties, ABS plastic occupies an important position in the electronics industry, machinery industry, transportation, building materials, toy manufacturing and other industries, especially for slightly larger box structures and force-bearing components. , decorative parts that require electroplating are inseparable from this kind of plastic.

The largest application fields of ABS injection molded parts processed by precision injection molding are mainly in automobiles, electronic appliances, building materials and DIY production fields.

ABS plastic injection moulding products are also widely developed and used in automobile parts manufacturing, such as vehicle head lamp cover, automotive tail light housing, automobile dashboards, body exterior panels, interior decorative panels, steering wheels, sound insulation panels, door locks, bumpers, ventilation ducts and many other components.

ABS plastic injection moulding parts are widely used in internal and external components of refrigerators, televisions, washing machines, air conditioners, hair dryers, microwave ovens, computers, copiers and other electronic appliances.

ABS plastic injection molded components mainly include ABS pipes, ABS sanitary ware, ABS decorative panels, etc.

Injection molded ABS plastic articles mainly include meter covers and casings, instrument panels, instrument casings, etc.

In addition, ABS injection molded parts are also widely used in packaging, furniture, sports and entertainment products, and machinery industry.

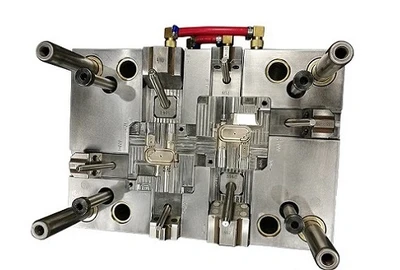

Steel is one of the key materials for mold making. However, different plastic properties have different needs for mold steel. How to choose the appropriate steel is an important part of ABS mold production.

We will introduce the types of steel materials and their characteristics required for making ABS plastic molds and how to choose suitable steel materials to ensure the quality of custom abs plastic molding products.

P20 steel is one of the most widely used steel materials in ABS plastic mold making. It is characterized by high hardness, good cutting performance, good heat resistance, good processing performance and high toughness. Molds made of P20 steel can be suitable for the production of medium to large plastic products.

718 steel is also one of the commonly used steel materials in ABS plastic mold making. It is characterized by high hardness, high compressive strength, high heat resistance and good corrosion resistance. Molds made of 718 steel are suitable for the production of large and complex plastic products, such as automobiles, electrical appliances, etc.

2316 steel is a high-grade steel used in ABS plastic mold making. It is characterized by excellent heat resistance, corrosion resistance and toughness, and is suitable for making high-quality, high-precision molds.

There are many varieties of ABS, and the barrel temperatures of different varieties are different. The barrel temperature of general ABS is 180-230°C, heat-resistant ABS is 190-240°C; and resistance ABS is 1πα2^0°. The nozzle temperature is 20-30°C lower than the front temperature of the barrel.

The mold temperature has a great influence on the quality of plastic parts. During molding processing, the mold temperature is generally controlled at 50-70°C.

The size of the injection pressure mainly depends on the structure and wall thickness of the plastic part. Usually, the injection pressure of general ABS is 50-70MPa, the injection pressure of heat-resistant ABS is 60~85MPa, and the injection pressure of flame-retardant ABS is 60-100MPa. If the flow resistance during mold filling is large, use a higher injection pressure; otherwise, use a lower injection pressure.

Medium injection speed is better for ABS materials. When the injection speed is too fast, the plastic is easy to burn or decompose and release vaporized materials, resulting in defects such as weld seams, poor gloss, and redness of the plastic near the gate on the parts. However, when producing thin-walled and complex parts, it is still necessary to ensure a high enough injection speed, otherwise it will be difficult to fill.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.