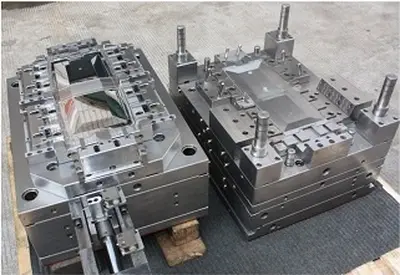

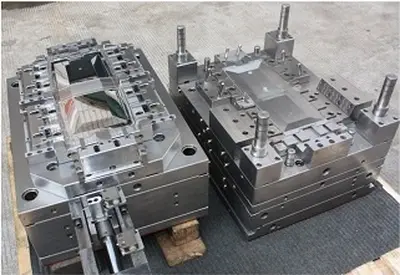

There are many kinds of CNC plastic molds, which can be classified according to forming material, forming process, loading and unloading mode, cavity number, parting surface characteristics, forming process, fixing mode and so on.

There are too many methods and the situation is complicated. This article will share some of the classifications of CNC plastic mold, so that you can understand its application and related knowledge more clearly. Knowledge is slowly accumulated, I hope you can always keep the enthusiasm of learning, learning endless.

Now let's get to know!

1. Injection Molding

At a certain temperature, the fully melted plastic material is stirred by screw, injected into the die cavity by high pressure, and then cooled and cured to obtain the method of forming products.

2. Extrusion Molding

Material through the role of extruder barrel and screw, while being heated and plasticized, while being pushed forward by screw, continuous through the machine head to make a variety of cross-section products or semi-products of a processing method.

3. Blow Molding

By means of gas pressure, the hot melt billet closed in the die is blown to form a hollow product. Blow moulding moulds only have negative moulds (concave moulds), which can shape products with complex undulating curves (shapes).

4. Gas-assisted moulding

When the plastic fills into the cavity properly (75%~99.9%) the inert high-pressure nitrogen gas is injected. The gas-driven melt plastic continues to fill the cavity. Gas packing is used to replace the plastic packing process as an injection moulding technology.

5. Vacuum forming

Vacuum moulding is often called suction moulding, which is a plastic processing technology. The main principle is to use the vacuum to adsorb on the surface of CNC plastic molds after heating and softening the flat hard plastic sheets, and then to form after cooling.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.