There are two templates on the injection molding machine, one is fixed and called the fixed template, and the other can move, called the moving template. The mold is fixed on these two templates through screws and compression plates. When the mold is opened, the moving template of the injection molding machine moves and drives the mold to open.

After the mold is manufactured, it needs to be injected and molded, placed on the injection molding machine, and the production of the product begins. However, there are many models of injection molding machines, and each type of injection molding machine has its own parameters. The injection molding mold design must be able to meet the requirements of the injection molding machine type provided by the customer, otherwise it will not be able to produce.

The injection amount is the maximum mass value (or volume value) of molten glue that the injection molding machine can shoot at one time during production, which represents the maximum injection capacity of this type of injection molding machine. The amount of molten glue used in a mold in the injection moulding tool design must be smaller than the injection amount of the injection molding machine. Otherwise, the product cannot be fully filled and the production cannot be carried out.

This is the compressive force on the template when the mold is closed on the injection molding machine. The locking force required by the molded product during molding must be less than the rated locking force of the selected injection molding machine. Otherwise, molten glue is easy to leak from the parting surface, resulting in flying edges.

There are four pulling rods in the dead corners of the fixed template and the moving template of the injection molding machine, which are used to ensure sufficient strength and rigidity of the injection molding machine and are responsible for sliding the template. However, it often limits the external size of the mold, because the mold is hung from the middle of the pulling rod during installation.

The external dimensions of the mold cannot be greater than the corresponding pulling rod spacing at the same time. If the length of the mold exceeds one pulling rod spacing, check whether the mold can be rotated and hung in the rod space. If it cannot be carried out by rotating, then the mold size can only be changed or the injection molding machine can be replaced.

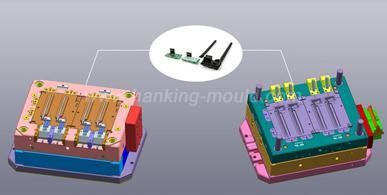

HanKing Mold designs and manufactures plastic injection molds in China, providing large factories for our global customers, and also provides injection molding production services, including secondary processing and assembly. Our global customers come from the United States, Germany, Switzerland, France, Italy, Austria, Israel and other parts of the world. The company's business philosophy is "customer first and quality first", and is a trustworthy injection mold manufacturing company. Welcome to consult us.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.