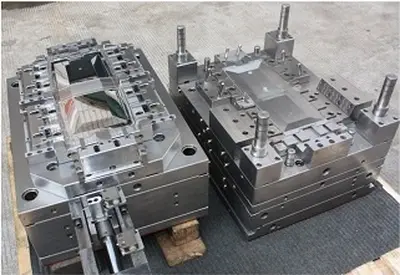

Due to the high processing accuracy requirements of injection mold manufacturing, the production and processing technology is also more complicated, so the processing and production costs of general plastic injection molds are relatively high. Injection moulding moulds manufacturer all want a longer service life of the mold. Therefore, the requirements for the use and maintenance of the mold are higher, in order to maintain the working accuracy and prolong the service life. Whether the selection of injection mold materials is reasonable or not is also an important condition for prolonging the service life of the mold.

The materials selected for injection mold manufacturing must meet the following requirements:

1. Injection molding mold steel must have good processing properties, so that the deformation will be small when working in a high temperature environment and heat treatment.

2. The working surface of the melt runner in the cavity of the mold should deal with low negative force of the material flow. In this way, the surface roughness of the working surface should be reduced, the steel should have good polishing performance, and there should be no impurities and no pores in the material.

3. Excellent wear resistance. In order to maintain the dimensional accuracy of the mold structure for a long time, it is very necessary to require the working surface of the mold after processing to be wear-resistant. Especially when the glass fiber hard filler is contained in the raw material of the processed molded product, it is very easy to accelerate the wear of the mold working surface. For such a mold, it must have sufficient hardness and wear resistance.

4. The steel has good corrosion performance. In the plastic melt molding production process, plastic raw materials and some auxiliary materials have to contact steel, which has a certain chemical corrosion effect on steel. In order to maintain good corrosion resistance of the mold, corrosion-resistant alloy steel or high-quality carbon steel must be selected, and the surface should be chrome-plated or nickel-plated if necessary.

5. The steel should have sufficient working strength. In addition to a certain degree of hardness after surface heat treatment, the selected steel should also have sufficient core strength. Since the injection mold has to withstand a lot of injection pressure and clamping force, the core strength of the steel used in the injection mold must be considered.

If you want to know more about the injection mold, you can contact us immediately, we will serve you wholeheartedly.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.