HanKing Mould is rooted in the plastic products industry for 20 years, through continuous efforts via HanKing people, we have become a group company. Following the establishment of a professional precision injection mould factory in Shenzhen in 2017, which specializing in the production of export molds. Due to business growth, a large injection molding plant was established in Dongguan in 2021, our new plastic injection molding shop is equipped 27 sets of injection molding machines, in addition to the original 8 injection molding machines at Shenzhen factory, we have total of 35 injection molding machines and more than 100 employees. The machine range from 60ton to 1600 ton, is able to produce most sizes of plastic products, we provide large part injection molding in China with low cost and fast lead time, the largest plastic part we can produce reach to maximum 8000g. That is because all our injection molding machines are equipped with robot, this allows us to provide 24-hour fully automated production services.

Please follow us, let’s show our new injection molding factory.

Injection molding workshop on the first floor, in this picture we can see Haitian injection molding machines include 320ton, 380ton, 470ton, 530ton, can help customer produce most middle size plastic products.

Since we provide large part injection molding in China, large-scale machines are indispensable.

For plastic products of more than 1000 gram, you will need our 800-ton injection molding machine, theoretical shot size is 2799 gram, max mold size can reach 980mm.

Generally speaking, choosing the size of an injection molding machine is not only based on the size of the plastic part, but also depends on the complexity of the product, so we had three 1000ton injection molding machines, clamping force reach to 10000.

For more large injection molding part, we have 1400ton machine, theoretical shot size is 7300 gram.

Currently our largest injection molding machine is 1600ton, theoretical shot size is 9067 gram.

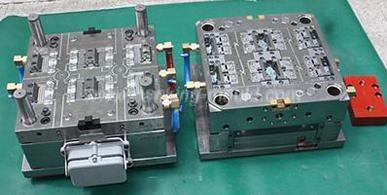

As a modern enterprise integrating precision mold making, injection molding production and secondary processing, we have obtained ISO9001:2015 & IATF 16949 certification. At any time, we are ready to provide good quality injection molds as well as nice molding plastic parts to all customers.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.