PC plastics will also hydrolyze and break bonds, reduce molecular weight and physical strength when encountering very low moisture. Therefore, before molding, the moisture content of polycarbonate should be strictly controlled below 0.02% to avoid reduced mechanical strength of the molded product or abnormal appearance such as bubbles and silver streaks on the surface. To avoid abnormal conditions caused by moisture, polycarbonate should be dried in a hot air dryer for more than three to five hours before processing, with the temperature set at 120℃, or treated with a dehumidification dryer, but the dehumidified air should have a dew point of -30℃ at the entrance of the funnel.

In order to meet the needs of various injection molding processes, polycarbonate has different melt index specifications. Generally, melt indexes between 5 and 25g/10min are suitable for injection molding. However, the optimal processing conditions vary greatly depending on the type of injection molding machine, the shape of the molded product, and the specifications of the polycarbonate, and should be adjusted according to the actual situation.

Key points for selecting injection molding machines

Clamping pressure:

The projected area of the finished product is multiplied by 0.47 to 0.78 tons per square centimeter (or 3 to 5 tons per square inch).

Machine size:

The weight of the finished product is about 40 to 60% of the capacity of the injection molding machine, which is the best. If the machine is expressed in polystyrene (ounces), it needs to be reduced by 10%, 1 ounce = 28.3 grams.

Screw:

The screw length should be at least 15 diameters long, and its L/D is 20:1. The compression ratio should be 1.5:1 to 30:1. The stop valve at the front end of the screw should be a sliding ring type, and the resin flow gap should be at least 3.2MM.

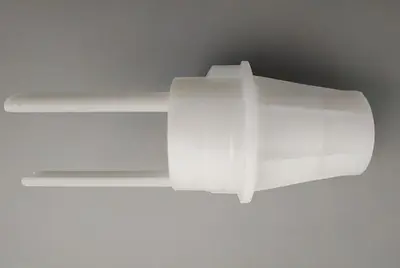

Nozzle:

The tip opening should be at least 4.5MM (diameter). If the weight of the finished product is more than 5.5KG, the nozzle diameter should be more than 9.5MM. In addition, the tip opening should be 0.5 to 1MM less than the gate diameter, and the shorter the section, the better, about 5MM.

Key points of molding conditions

Melting temperature and mold temperature:

The optimal molding temperature setting is related to many factors, such as the size of the injection molding machine, the screw configuration, the design of the mold and the plastic injection molded product, and the molding cycle time. Generally speaking, in order to allow the plastic to melt gradually, a lower temperature is set at the rear section of the material pipe/feeding area, and a higher temperature is set at the front section of the material pipe. However, if the screw design is improper or the L/D value is too small, the reverse temperature setting can also be used.

In terms of mold temperature, high-temperature molds can provide better surface appearance, less residual stress, and can also fill thinner or longer molded products. Low mold temperature can shorten the molding cycle.

Screw rotation speed:

40 to 70rpm is recommended, but it needs to be adjusted depending on the machine and screw design.

Injection pressure:

In order to fill the mold as quickly as possible, the higher the injection pressure, the better, generally about 850 to 1400KG/CM², up to 2400KG/CM².

Back pressure:

Generally, the lower the setting, the better. However, for uniform feeding, it is recommended to use 3 to 14KG/CM².

Injection speed:

The shooting speed is closely related to the gate design. When using direct gates or edge gates, a slower shooting speed is used to prevent the phenomenon of sunburst and wave flow marks. In addition, if the thickness of the finished product is above 5MM, slow injection will help to avoid bubbles or dents. Generally speaking, the shooting speed principle is that the thinner the faster, the thicker the slower.

Switch from injection molding to holding pressure, and the holding pressure should be as low as possible to avoid residual stress in the molded product. The residual stress can be removed or reduced by annealing; the condition is 120 to 130℃ for about thirty minutes to one hour.

Cylinder cleaning:

(1) At the molding temperature of polycarbonate, add the cleaning material (usually PP or PE) and inject it continuously for 20 to 30 times.

(2) Move the machine back and continue to inject the cleaning material until the injected cleaning material begins to expand and bubble.

(3) Reset the barrel temperature to 200 to 230℃.

(4) Continue to inject the cleaning material until the melt temperature of the cleaning material reaches 260℃ and the surface looks very clean and transparent.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.