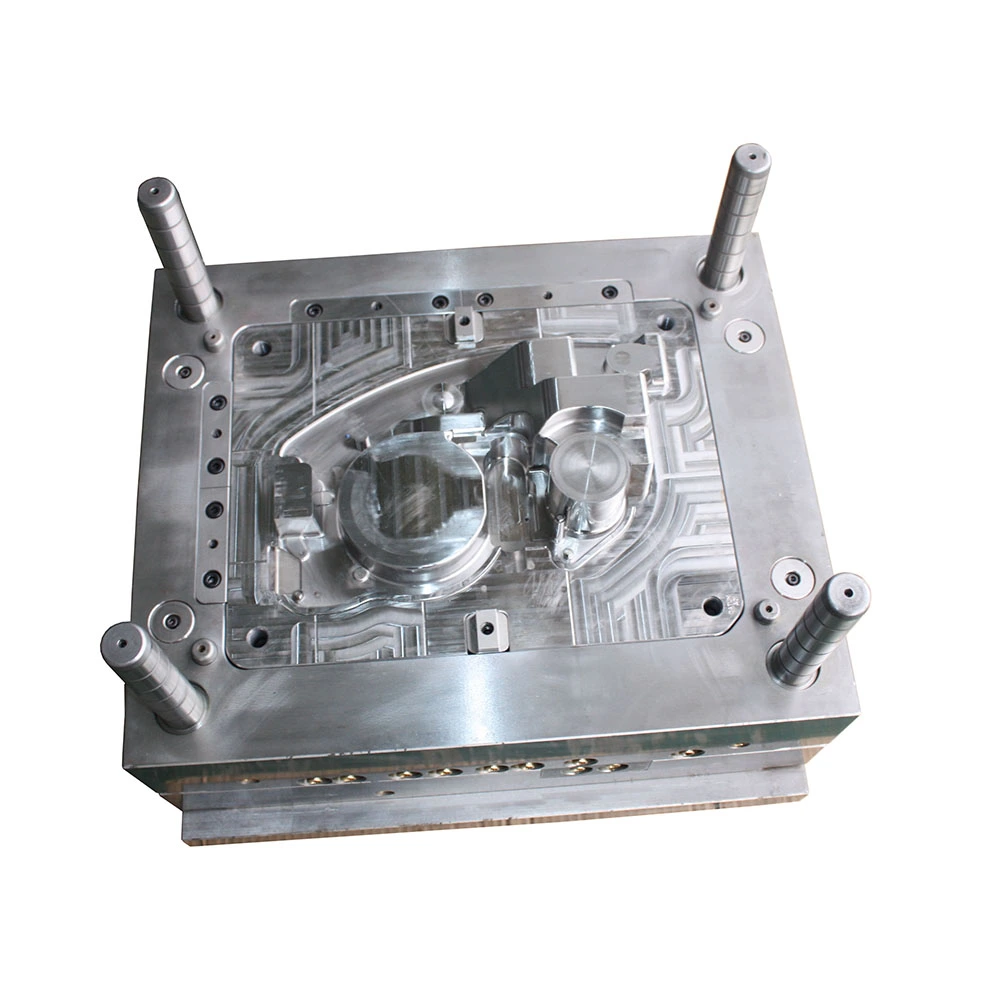

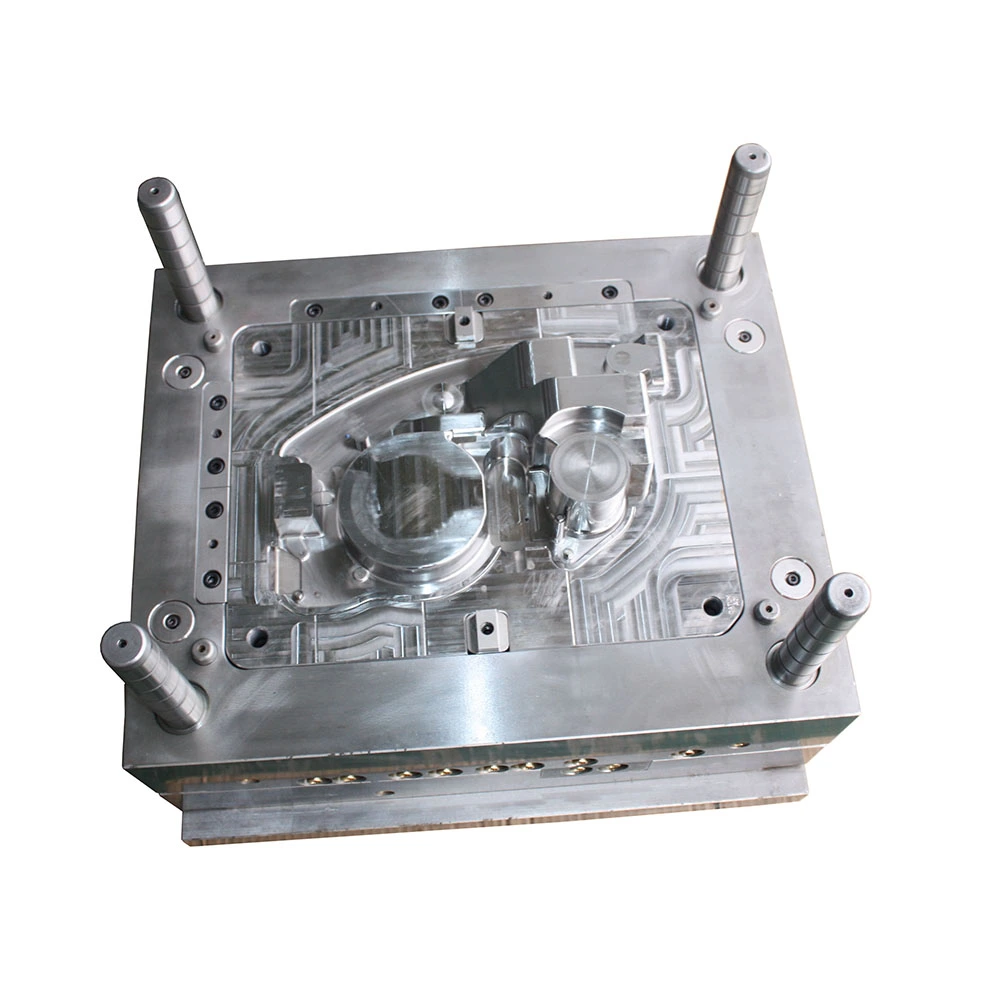

Product Name: Injection molding abs plastic

Part Material: ABS or other plastic

Product Color: Any color

Mold Cavity: 1 cavity or multi cavity

Surface: Matt or Glossy

Mold Injection System: hot runner or cold runner

Payment: to be negotiated

Supply ability: 30-40 sets mold each month

Lead Time: 3-4 weeks

MOQ: For mold 1 set, for plastic parts no MOQ

Place of Origin: China

Certification: ISO9001:2015

Shipping way: Sea, air, train, to be depended

Process: ABS injection molding process

HanKing Mould has a series of advanced equipments including Fanuc CNC machines, Sodick EDM machines, Sodick wire cut machines, Okamoto grinding machines, Yizumi Injection molding machines, Zeiss CMM, Easson 2D projector, and iMould Automatic System. We will do full dimension measurements for all injection mold components, copper and plastic parts.

China abs molding supplier of custom made plastic parts

1. Design improvement & Protype injection mould;

2. Professional DFM Report & Moldflow report before mold kick off;

3. Factory with injection molding machine from 60ton ~ 1600ton;

4. We will have engineers who are proficient in English to communicate with you.

Injection mold making capabilities:

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

Order process

RFQ -> Mold flow -> DFM analysis-> Mold design-> Design validation-> Tolerance analysis-> Mold making (full dimension measurement)->Mold trial (free samples, FAI, CPK)-> 4hours running ->Injection molding production

FAQ

Q1. Are you a factory or trade company?

We are a mold making manufacturer factory, in the beginning our factory is located at Shenzhen city, in year 2022 our factory moved to Dongguan city.

Q2. What kind of production service do you provide?

We provide all services for plastic injection mold making included part analysis, moldflow, mold design, mold manufacturing, plastic injection molding, etc.

Q3. What type of mold do you make?

We can make different kind of molds like single cavity, multi cavity mold, two shot mold, overmould, insert molding, etc.

Q4. How about the lead time?

Injection tooling making: 3-6 weeks

Molding production: 1-4 weeks

Q5. What documents or data are required for a quote?

It’s better please provide 3D files of the plastic product, resin, quantity of the injection parts, color and surface treatment

customer need.

Q6. How long should we take for a quotation?

This is depending by the mold quantities, normally for 1 mold, we are able to quote within 24 hours.

Q7. What is payment term in YF mold?

Mould: 40% prepaid, 30% after the first trial sample is confirmed receipt, 30% balance before mold shipping or the mould is finished.

Molding parts: 30% prepaid, balance T/T before shipment.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.