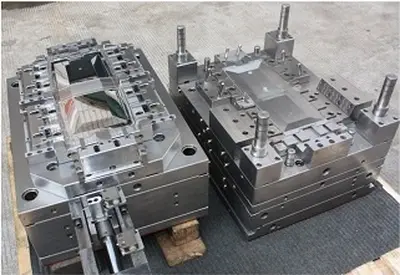

The Ultimate Guide to Cleaning Plastic Injection Moulds

We're diving into the ins and outs of keeping your plastic injection moulds squeaky clean. These essential tools play a vital role in the production process, and proper maintenance is key to ensuring top-notch results. Let's roll up our sleeves and get ready to banish those mouldy issues once and for all!

Understanding the Importance of Cleaning

Picture this: you've just completed a production run, and your mould is caked with leftover material. Not only does this gunk affect the quality of your products, but it can also lead to costly downtime and repairs down the line. Regular cleaning is a preventative measure that keeps your moulds in tip-top shape and your production line running smoothly.

Tools and Materials Needed

Before you get started, gather your trusty toolkit. You'll need mold cleaning brushes, a mold cleaner suited to your plastic resins, compressed air for those hard-to-reach spots, and lint-free cloths to wipe away residue. Don't forget to suit up with gloves and goggles to protect yourself from any harsh chemicals!

Pre-Cleaning Procedures

Prior to diving into the cleaning process, it's crucial to let your mould cool down. This not only makes the cleaning process safer but also prevents warping or damage to the mould itself. Safety first, plastic injection moulder!

Cleaning Process

Now, onto the nitty-gritty of cleaning your plastic injection mould. Start by carefully disassembling the mould to access all its nooks and crannies. Using your chosen mold cleaner and brushes, scrub away any residue and debris that have built up. Pay close attention to cleaning vents and cooling channels to maintain optimal performance.

Post-Cleaning Procedures

Once your cleaning mission is complete, make sure to thoroughly dry the mould before putting it back together. Take this opportunity to inspect the mould for any signs of wear and tear. Catching these issues early can prevent bigger problems down the line.

Maintenance Tips

Regular maintenance is key to keeping your plastic injection moulds in prime condition. Establish a cleaning schedule to prevent buildup and extend the life of your mould. When the mould is not in use, store it properly to shield it from dust and damage.

Conclusion

And there you have it - your comprehensive guide to keeping your plastic injection moulds spick and span! By prioritizing regular cleaning and maintenance, you can ensure that your production line runs smoothly and your products are top-notch. So, roll up your sleeves, grab those cleaning supplies, and let's banish those mouldy issues for good!

Remember, a clean mould is a happy mould! Happy plastic injection molding manufacturing!

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.