Introduction to Injection Moulding

Have you ever wondered how plastic toys, containers, or even parts of your favorite gadgets are made? Well, one fascinating process that helps create all these things is called injection moulding. Let's dive into the world of injection moulding to understand how it works and why it's such an essential technique for crafting items out of plastic.

What is Injection Moulding?

Injection moulding is like a magical transformation where plastic is melted down and then shaped into new objects. Imagine a mold as a special cookie cutter that shapes the melted plastic into the exact form needed. This method is like pouring liquid plastic into a mold and watching it harden into a solid shape, just like making ice cubes in an ice tray.

Why Use Injection Moulding?

Injection moulding is like having a super-fast and precise way to make many copies of the same thing. It's like having a magical machine that can create identical plastic pieces over and over again with incredible accuracy. This method is not only quick but also helps in producing items neatly and efficiently, making it a popular choice for manufacturing various plastic products.

Getting Precise: How It Works

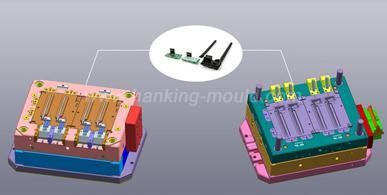

When it comes to precision moulding techniques, the first step is designing the mould. Imagine you have a special cookie cutter that shapes the plastic into the exact thing you want. People who work with custom injection moulding think up and create these special shapes, called moulds, to make all kinds of plastic items.

Choosing the Plastic

Just like picking the right ingredients for a recipe, choosing the right kind of plastic is super important in the plastic injection process. Different plastics have different properties, like being strong or flexible. So, it's essential to select the plastic that will work best for the job at hand.

The Moulding Process

Now, let's dive into how the actual moulding process works. First, the chosen plastic is melted until it's like gooey cheese. Then, this melted plastic is injected into the mould, where it cools down and hardens into the shape of the mould. It's like pouring liquid into a mold and waiting for it to set into a solid shape!

Solving Problems with Industrial Moulding

When it comes to solving big problems, industrial moulding solutions are the way to go. Factories use large machines to create a high volume of plastic parts quickly and efficiently. This is especially important for industries that require mass production, such as automotive, electronics, and medical equipment manufacturing.

Making Strong and Safe Parts

One of the key advantages of using precision moulding techniques in industrial settings is the ability to create strong and durable parts. Products made through injection moulding are designed to withstand rigorous use and are built to last. This is crucial, especially in industries where safety and reliability are paramount, like in the production of medical devices or automotive components.

Custom Creations: Making Special Things

Customization is like ordering a pizza with your favorite toppings—it's making something just the way you like it. When we talk about injection moulding customization, it means creating unique and special items that are tailored to specific preferences or needs. Just like how you can choose your toppings on a pizza, customization allows you to pick the colors, shapes, and sizes of the plastic items being made.

Creating Bespoke Components

Some things made with injection moulding are designed to fit a special need or job. These bespoke plastic components are carefully crafted to serve a specific purpose, whether it's a custom tool for a factory, a unique part for a machine, or a personalized accessory. By using precision moulding techniques, manufacturers can create one-of-a-kind items that meet individual requirements.

The Future of Injection Moulding

Injection moulding has been around for a long time, but the future holds exciting possibilities for this innovative process. Let's take a peek into what the future might look like for injection moulding.

New Materials and Ideas

One of the most exciting things about the future of injection moulding is the discovery of new materials and ideas. Scientists and engineers are constantly exploring different types of plastics and how they can be used in the moulding process. These new materials might be stronger, more flexible, or even more environmentally friendly than traditional plastics.

Making Moulding Even Better

As technology advances, so does the process of injection moulding. Engineers are always looking for ways to improve the efficiency and precision of moulding techniques. This could mean faster production times, more intricate designs, or even the ability to create larger and more complex components. The future of injection moulding is all about pushing the boundaries of what is possible.

Conclusion

Injection moulding is a super cool way to make all sorts of things out of plastic. We learned that it involves melting plastic and shaping it into new stuff. This method is awesome because it can make lots of the same thing really quickly and neatly. It's like magic, but with plastic!

Not only is injection moulding great for making things fast, but it also helps in creating precise and detailed items. By carefully designing the mould, choosing the right plastic, and following the injection mold manufacturing process step by step, we can get some really amazing results.

Whether it's for big industrial jobs or for creating custom and unique components, injection moulding has got us covered. It's used in factories to make tons of products, ensuring they are strong and safe for everyday use. And for those special, one-of-a-kind items, injection moulding customization allows us to tailor-make products to suit specific needs.

Looking ahead, the future of injection moulding seems bright. With new materials and ideas constantly being discovered, there's no telling what incredible things we'll be able to create. Scientists and engineers are always working to make injection moulding even better, pushing the boundaries of what's possible with this innovative technology.

So, next time you see a plastic product, remember that it might have been made using injection moulding. It's a fascinating process that plays a big role in our everyday lives, shaping the world around us in more ways than we might realize.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.