In order to maintain the machining accuracy of plastic injection mould under injection pressure and clamping force, it is necessary to consider the feasibility of grinding and polishing of the cavity parts must be considered when designing the mould structure. The plastic injection mould cavity, mould core processing has reached the requirements of high machining accuracy, and the shrinkage rate is the same as expected. However, it is difficult for the inner and outer dimensions of the moulded products to meet the design requirements of plastic parts due to the deviation of the centre during moulding. The guide pin and guide sleeve, which are commonly used in the mould, are set to maintain the dimensional accuracy of the front and rear mould cavities on the parting surface. In addition, it is necessary to install a tapered locating pin or wedge-shaped locating block to ensure accurate and reliable positioning accuracy of plastic injection moulds.

High-quality alloy tool steel with high mechanical properties and small thermal creep needs to be selected as the material used to make plastic injection moulds. The mould material for making the cavity and runner should be the material with high hardness, good wear resistance, strong corrosion resistance and thermal deformation after strict heat treatment. At the same time, the difficulty and economy of machining processing and electric processing should be taken into consideration. In order to prevent the change of the dimensional accuracy of plastic injection mould due to aging, it is necessary to reduce the tempering or low-temperature treatment of the remaining tissue of the heat treatment of the mould material. It is necessary to specify tempering treatment or low-temperature treatment to reduce the residual tissue of the heat treatment of mould materials when designing the mould.

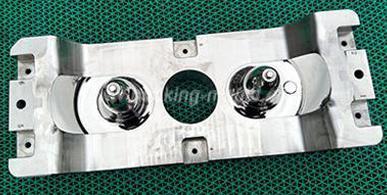

For vulnerable parts of plastic injection moulds, especially vulnerable parts such as the mould cavity and the mould core. The possibility of maintenance should be considered in the design to maintain the high accuracy of the die after maintenance.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China