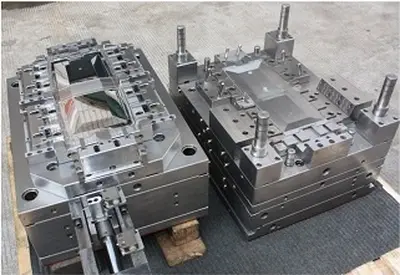

For plastic mold making company, as the quality of the mould directly determines the production efficiency of injection molding and the quality of the product, which determines the added value of the product, how to efficiently cool the plastic products in the minimum cycle time has become a key factor for the major plastic mold making company to consider, and cooling plays an important role in this period.

The principle of conformal cooling is to rapidly reduce the temperature of the plastic parts in a uniform and continuous way. The injection parts can not be removed from the mold during the cooling process until they are fully cooled. Then, the injection parts can be removed from the mould. Any hot spot will delay the injection cycle of the injection parts, which may cause warpage and depression of the injection parts after demoulding, and may damage the surface quality of the parts.

Rapid cooling takes heat away from the injection part by the passage of coolant in the mold. The speed and uniformity of this cooling effect are determined by the passage of fluid and the speed of cooling fluid through it.

The cooling passage in the mold produced by the traditional plastic mold making company is realized by secondary processing. Through cross-drilling, the inner network of the straight-line pipe is generated, and the flow velocity and direction are adjusted by the built-in fluid plug. This method has its limitations. The shape of the water network is limited. Therefore, the cooling channel is far from the surface of the die, which makes the cooling efficiency low. Not only that but also have to face the additional processing and assembly time, as well as the risk of blocking the blind channel network; moreover, in complex circumstances, in order to reserve the cooling channel processing, the die also needs to be cut into several parts to manufacture, and then spliced into a whole die, which leads to additional manufacturing links, and also shortens the life of the die.

The difference between conformal cooling and traditional cooling is that the shape of the cooling channel changes with the shape of the injection products, and it is no longer linear. This cooling channel solves the problem of inconsistent distance between the traditional cooling channel and the surface of the die cavity, which can make the injection products cooled uniformly and have higher cooling efficiency.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China