In the two-color mold injection molding process, determining the cooling time affects not only the product quality but also the output and the cost of the product. Transfer the necessary heat from the plastic melt injected into the mold cavity to turn it from the melt into a solid so that it can be taken out of the mold without being deformed. Therefore, the correct estimation of the cooling time has become the leading process parameter that should be determined first in the injection molding process. So what will affect the cooling rate of the two-color mold?

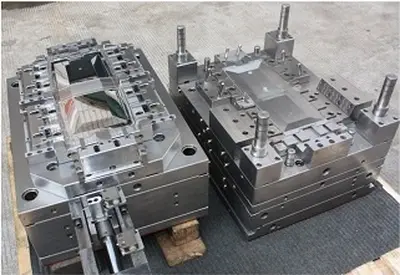

1. Mold materials and cooling methods

When it comes to mold materials, the mold core, cavity materials, and mold base materials significantly influence the cooling rate. The higher the thermal conductivity of the two-color mold material, the better the effect of transferring heat from the plastic per unit time, and the shorter the cooling time.

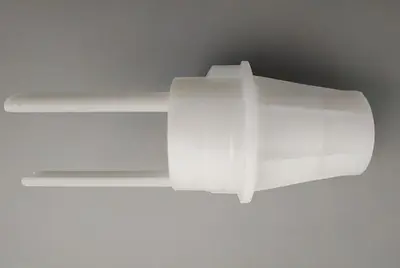

2. Plastic products design

The thicker the plastic product and the two-color mold product, the longer the cooling time.

3. Plastic selection

It refers to measuring the speed at which plastic conducts heat from a hot place to a cold place. The higher the thermal conductivity of the plastic, the better the heat conduction effect. If the plastic's specific heat is lower, the temperature is likely to change, so the heat is quickly dissipated, the heat conduction effect is better, and the required cooling time is shorter.

4. Methods of cooling water pipe configuration

The closer the cooling water pipe is to the mold cavity, the larger the pipe diameter, and the larger the number, the better the cooling effect and the shorter the cooling time. The larger the flow of cooling water, the better the impact of cooling water to take away heat by heat convection.

5. The characters of the coolant

The coolant's viscosity and thermal conductivity will also affect the thermal conductivity of the two-color mold injection. The lower the viscosity of the coolant, the higher the thermal conductivity, and the lower the temperature, the better the cooling effect.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.